Fuel, air, and spark – the fundamental ingredients of combustion are simple. Getting the most “bang for your buck”, however, is an entire field of science, engineering, and technology. Let used-oil-combustion experts, EnergyLogic, break down the science of a clean-burning waste-oil heater.

The Science of Combustion

Converting fuel into useful energy is easy. Just feed the right ingredients into a controlled environment, start a chain reaction, and keep supplying the reaction as long as desired. On paper everything is neat and tidy.

Just mix the right amount of hydrogen rich fuel (like hydrocarbon)with the precise amount of oxygen-containing air at just the right temperature and pressure, and BOOM! You’ve rearranged these chemicals into carbon-dioxide, water, light, and HEAT to keep you warm or drive some other process.

But this kind of Goldilocks scenario only purely exists on paper, with the other storybooks, or in highly controlled laboratories with idealized conditions.

Undesirable By-Products of Combustion

In our everyday practical reality, things are usually a bit messier. When combustion conditions are not ideal, side reactions or missed reactions result in unburned fuel, reduced efficiency, and other undesirable by-products like carbon-monoxide, smoke, and carbon buildup.

Even the cleanest, most eagerly combustible fuels face this reality. And while heavier, less-traditional fuels (like used oil) present additional challenges to combustion, they also contain loads of valuable energy. And where there’s energy, there’s opportunity!

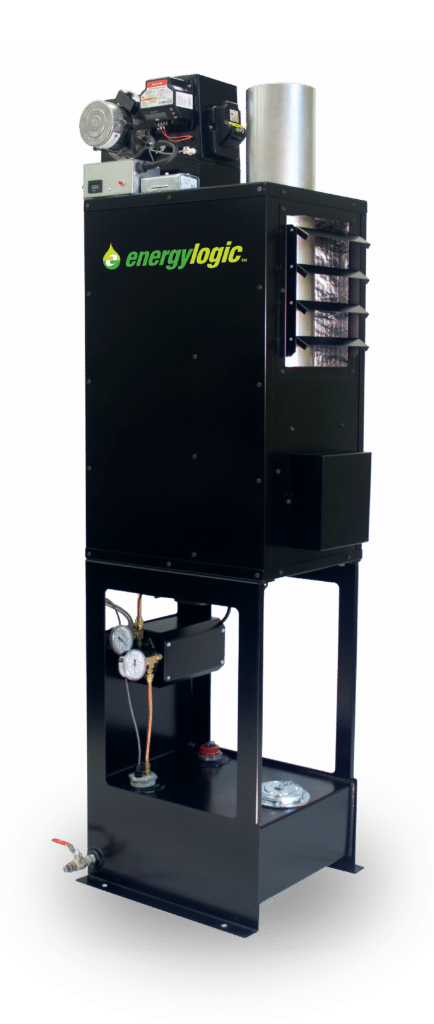

EnergyLogic Offers Clean, Efficient Combustion Systems

EnergyLogic uses a combination of technologies and engineering approaches to control and contain the clean, efficient combustion of a wide variety of fuels in the same furnace, with no adjustments necessary when switching or blending fuels. This is accomplished by making smart, passive optimization features standard and by developing new systems along the way to making waste-oil recycling easier and more beneficial for you.

Dedicated Tank for Waste Oil

We start by building a tank dedicated for waste oil. The dedicated tank improves fuel quality by discouraging the collection of contaminants and allowing water and solids to settle below the fuel-pickup port.

Metering Pump for Precise Fuel Volume

Fuel is then filtered through a set of fine steel screens and pumped using a metering pump, rather than a pump that relies on high fuel pressure. The metering pump allows the fuel to be delivered at a precise volume regardless of weight, temperature, or viscosity, ensuring just the right amount of fuel enters the combustion process at all times.

Patented Pre-heating Process to Achieve Flash Point Temperature

The fuel then passes through a patented preheating process to bring it up to a temperature that approaches the flash point of heavier fuels like waste oil, making sure that whatever the type or source of fuel, it enters the combustion process ready-to-go.

On-Board Air Compressor to Deliver Clean Air

An on-board air compressor delivers just the right amount of clean, dry air to blend with the fuel. A special nozzle sprays the used oil as a fine mist, maximizing the surface area and making the waste oil available to interact with combustion. Continuous spark is introduced to the spray and a blower motor brings in excess oxygen while getting the whole thing moving in the right direction.

Tools for Proper Draft

So far, we have all the right ingredients to create flame, but there are few more key steps to containing and controlling the flame to maximize efficiency and flame temperature.

Proper draft through a chimney flue is crucial to complete combustion. Draft helps to mix the combustion ingredients together and evacuates the resulting exhaust to allow for a continuous, stable reaction. But too much draft allows heat to leave too quickly, before it can be transferred to the useful side of the heater, reducing efficiency. Too little draft allows exhaust to build up and creates dirty, undesirable byproducts.

EnergyLogic provides tools to set up and monitor the perfect draft for your unique installation to ensure that you get the most from your waste oil.

Air Shutter for Precision Excess Air Intake

Excess air is also necessary for heavy fuels like used oil. However, too much air will not be consumed in the process and will only cool it down. Too little air will starve the reaction and result in the afore-mentioned undesirables. EnergyLogic throttles the intake of the blower with an air shutter that is set to provide just the right amount of air to match the fuel provided by the metering pump, Goldilocks-style.

See how everything is working together?

The air shutter also allows for field adjustments to compensate for things like altitude or odd fuel properties. However,once your system is dialed in, it’s optimized and ready-to-go when you are, regardless of temperature swings or normal variations in fuel type or blend.

Patented Flame-Retention Head

There is one finishing touch to creating the hottest flame. EnergyLogic uses a patented flame-retention head, positioned just in front of the nozzle. The flame-retention head contains combustion and adds the final controls for blending ingredients and maintaining reaction temperature.

Learn More About How EnergyLogic Achieves a Hotter Flame

Together, EnergyLogic’s advanced technological components create a combustion system that is guaranteed to provide a clean, complete burn of your used oil and minimize exhaust and heat loss.

Let EnergyLogic lend decades of practical and engineering experience to your facility while helping you save money and the environment today!

Get started below