How do waste oil burners work?

✅ Turning waste oil into heat involves two key aspects: burning the oil and venting the warm air produced into the main space or system to be heated.

✅ The most effective and efficient waste oil burners are built with quality components.

✅ A waste oil burner with advanced burner technology can produce a hotter flame, which maximizes heat output and produces less ash to clean up.

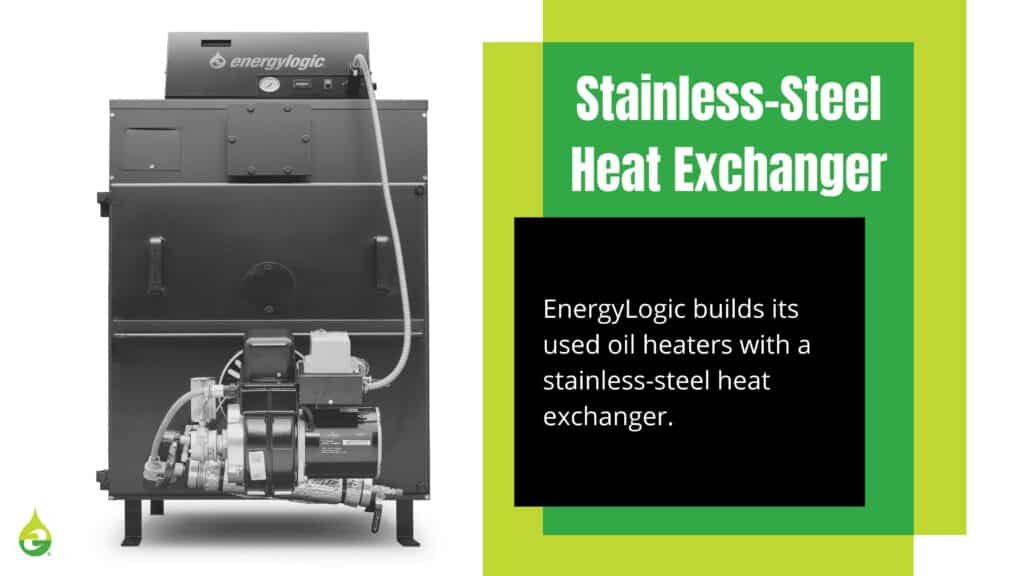

✅ A stainless-steel heat exchanger on the waste oil heater generates heat faster and is more resistant to breakage and warping.

✅ An onboard air compressor improves a waste oil burner’s safety, reliability, and overall efficiency.

✅ Side suction metering pumps provide an accurate fuel flow rate and consistent delivery of fluids without effort from the operator.

✅ EnergyLogic can create a custom waste oil heater or boiler solution to provide heat to your space with the right accessories and the best technology available in the industry.

Turning waste oil into heat involves two key aspects: burning the oil and venting the warm air produced into the main space or system to be heated.

Burning the oil begins with pumping the waste oil from a storage tank through a filtration system. The filtered waste oil is then pumped into the burner system. Here the waste oil is heated to the perfect temperature for more complete and even combustion.

Once the oil is heated, a heat exchanger helps vent the warm air into the designated space. This process begins with spraying the pre-heated oil into a blast tube where the oil mixes with air. Next, a high-voltage electric current ignites the heated mix of waste oil and air and passes over the heat exchanger to extract the heat from the ignition. All this heat is vented out to the main space or system to be heated. Finally, a chimney vents any excess gas into the outside space.

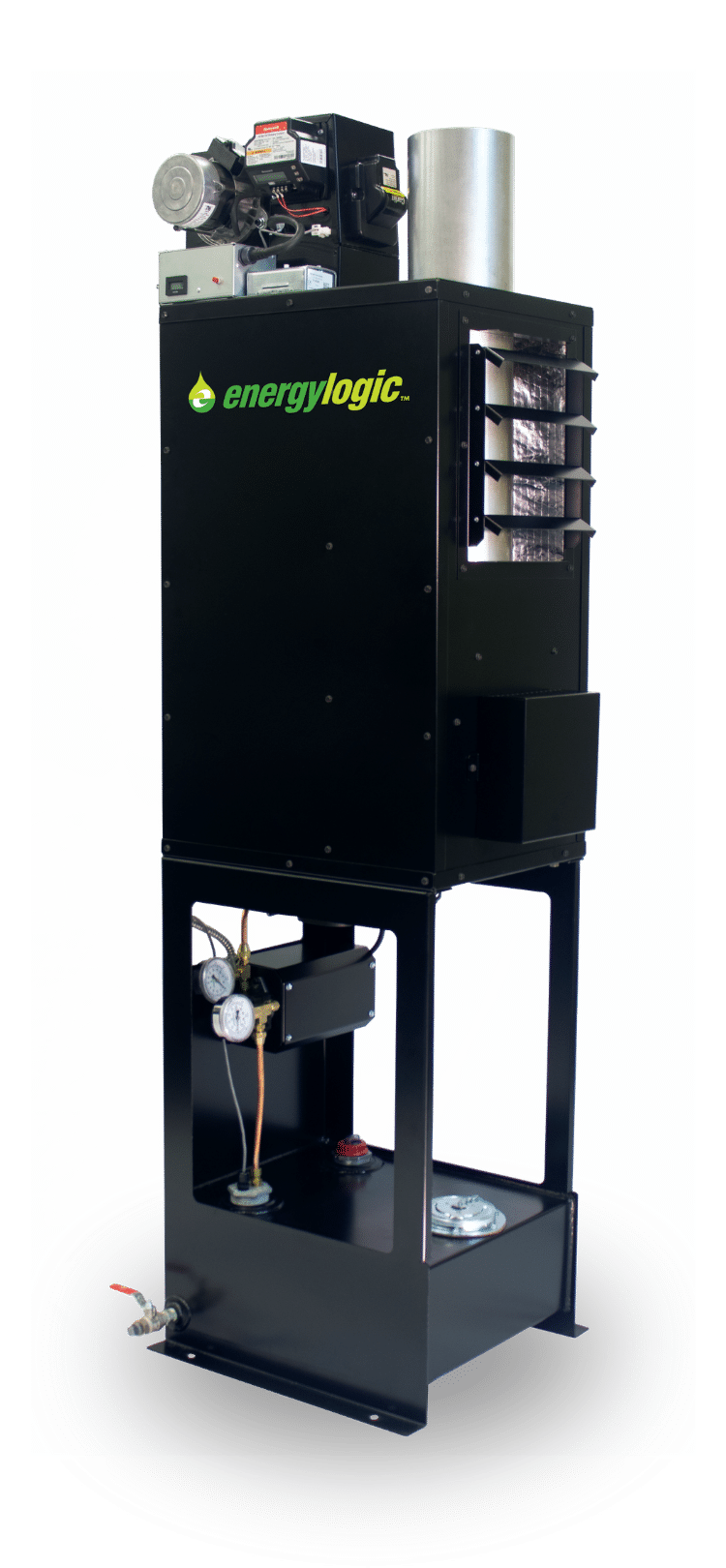

EnergyLogic Waste Oil Burners

EnergyLogic understands that the most efficient and effective waste oil burners are those that offer the most complete combustion. Through our 40 years of experience in waste-oil combustion, EnergyLogic has developed best-in-class technology that produces the hottest flames and complete combustion. This means our patented waste oil burners deliver the most heat while requiring the least maintenance. Moreover, our systems burn the broadest range of recycled fuels.

An Effective and Efficient Waste Oil Burner Begins with Quality Components

From our advanced burner to the industry’s leading heat exchanger, EnergyLogic builds the most efficient and cost-effective waste oil heaters on the market. It’s the effectiveness of each waste oil burner component that makes EnergyLogic waste oil heaters stand out.

Advanced Burner Technology

Remember above when we said waste oil must reach a designated temperature before being fed into the combustion chamber to achieve complete combustion? Well, the heavier the oil, the lower the watt density (power) required to heat the oil to the proper temperature, making it vital to have the appropriate waste oil heater for the oil being used. Luckily, EnergyLogic’s used oil furnaces burn more types of fuels than any other waste oil heater. The range of fuels includes oils between 5 and 90 weight and even includes synthetics. That means our advanced burner technology can maximize the output and the efficiency of the waste oil being burned. That hotter flame isn’t only more effective, it also produces less ash, so there’s less maintenance and cleaning required.

Stainless Steel Heat Exchanger

At the heart of waste-oil combustion technology is the heat exchanger. The heat exchanger is the component that transfers the energy from the oil into heat. Therefore, it is an important component to optimize. EnergyLogic builds its used oil heaters with a stainless-steel heat exchanger. Stainless steel is a superior heat conductor at operating temperatures, which allows our recycled oil furnace systems to generate heat faster. Additionally, stainless steel is better than aluminum, iron alloys, or steel alloys at withstanding corrosion at higher temperatures over time. This ensures that EnergyLogic’s waste oil heaters are not only light, but resistant to breakage and warping. We are so confident of the reliability of our stainless-steel heat exchangers that we offer the industry’s first and only money-back guarantee.

Onboard Air Compressors

Oxygen is an essential element of combustion. Along with a source of fuel and ignition, an adequate supply of combustion air is vital to the heating unit’s performance and operation. This is particularly true in waste oil burners. The air compression system component installed in your waste oil burner significantly affects your heating unit’s safety, reliability, and overall efficiency. At EnergyLogic, we include onboard air compressors as standard equipment. An onboard air compressor versus an external compressed air system allows an EnergyLogic waste oil furnace to operate overnight without the risk of a fire. Additionally, our high-performing onboard air compressors provide the right amount of air where and when you need it with little to no manual adjustments throughout its lifetime. Finally, onboard air compressors provide efficient and complete fuel combustions, regardless of changes in fuel viscosity or flash point.

Patented Side-Suction Metering Pump

Proper combustion relies on the right balance of fuel, heat, and oxygen. Unfortunately, finding and maintaining this balance can require significant manual adjustments and costly periods of trial and error. However, EnergyLogic waste oil burners come with side suction metering pumps that provide an accurate fuel flow rate and consistent delivery of fluids without the effort from an operator. Our patented side-suction metering pump with meshed gears automatically calculates the exact amount of fuel to move for complete combustion, regardless of fuel density or viscosity. The result is better performance reliability, improved energy efficiency, and easier handling.

What Essential Components Should Your Waste Oil Heater Have?

EnergyLogic is committed to making heating with recycled oil both simple and effective. That is why we produce more waste oil heater accessories than most other companies in the industry.

If you are ready to turn your business’s waste oil into heat, then give us a call. We can build you a custom solution to provide heating in your space with the right accessories and the best technology available in the industry.

The Latest Innovation in Small Space Heating

Meet the EL 75H

Why our customers love us

Learn More about Waste Oil

Waste Oil Savings Calculator

Find Your Custom Solution - Start Here

Burn Waste Oil and Save:

Savings Per Year:(values in USD)

$ †Custom

10-year Savings(after equipment cost)

$ †Custom

An EnergyLogic Waste Oil Heater Pays for Itself in Only:

Years †Custom

†Custom: Is your facility not represented here?

Click Get Your Custom Quote to contact EnergyLogic for custom solution.

Information based on U.S. Energy Information Administration. *Based on insulated space with 16ft. ceiling. Results may vary based on geographical & other considerations.

You're making the best decision in waste oil heating.

Thank you for your interest in EnergyLogic!

An EnergyLogic Rep will be in contact within 1-2 business days to help you find the perfect heating solution for your facility.

Discover the Right Questions to Ask.

Download our Buyer's Guide, and be informed with insider industry knowledge.