EnergyLogic’s customer, a diamond mine in Southern Africa, recognized it needed to streamline its operations and find a way to minimize its environmental impact. They approached EnergyLogic with a set of unique waste oil disposal and heating challenges. Together with EnergyLogic’s expertise and the largest variety of accessories in the industry, the diamond mine achieved a customized waste oil collection and heating solution to their operational and logistical challenges.

Challenge No.1: Eliminate Disposal Costs for Waste Oil Generated On Site

The primary issue the customer faced was the disposal of used oil. The mine employs a mixed loading and hauling fleet comprising CAT excavators, along with CAT rigid dump trucks for hauling ore. This large fleet of mining equipment generates a lot of used oil. To add to the problem, the mine is over 10,000 feet above sea level. The site’s remote location makes it expensive and logistically challenging to have tanker trucks come in, pick up, and dispose of the waste oil.

Challenge No. 2: Heat a New, Large Service Area

The mountainous location of the client’s operations means that winter temperatures often dip below freezing. With the customer building a new service area, it only made sense to utilize their fuel resource in the waste oil generated to heat the shop.

Challenge No. 3: Generate Hot Water

The customer regularly washes their massive equipment onsite. This process requires a large amount of hot water to complete.

Challenge No. 4: A Plug-in and Go Solution Required

The final challenge that the diamond mine faced was a logistical one. Because of the remote location of the business, the solution needed to be as prepackaged as possible. Building a complete waste oil burner system on site would not be economically feasible. A designed system would be required to match the existing equipment and water storage.

Customized Solutions Developed by EnergyLogic

Together, the diamond mine and EnergyLogic discussed the challenges and specific needs of the client. To start, EnergyLogic would provide a waste oil collection system that would collect the waste oil in a storage tank and generate heat for the large tank of water that is used for washing the equipment. EnergyLogic would fit the customized solution in one shipping container measuring 40’L x 8’W x 9.5’H. The container would be shipped by ocean freight to the international customer in Southern Africa. Additional heaters would be designed to heat the new service shop area as well.

Solution No. 1: Supply a Complete System in a Shipping Container

One of the main requirements that the diamond mine had for its waste oil burner system was that it needed to be built off-site and installed on-site with little effort. EnergyLogic’s custom solution was to supply a complete system to burn used oil and make hot water inside a shipping container. Once the shipping container arrived onsite, all the client had to do was provide power, water, and oil, and the system would be up and running.

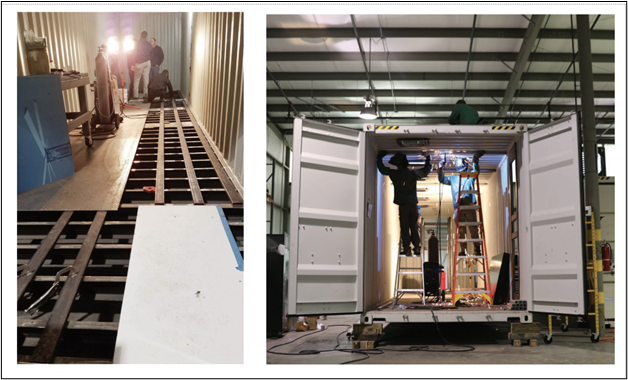

EnergyLogic modified a standard 40’ shipping container so that all of the equipment could be easily operated and serviced. This container had to address all of the extreme changes in weather along with the 10,000’+ altitude.

A 40’L x 8’W b 9.5’H shipping container awaits the installation of EnergyLogic’s customized waste oil burner solution for a Southern Africa diamond mine.

EnergyLogic engineers modifying a shipping container prior to fitting it with a customized waste oil burner system, complete with anti-skid flooring and a side door for personnel entry.

Solution No. 2: Install a Waste Oil Storage Tank

Since the boilers inside the container were consuming over 21 gals/hr, a buffer tank was required inside the container. A custom 500 gal tank was installed to provide the waste oil to the boilers using a reliable fuel delivery system. This custom autofill fuel system made it easy to fill the internal tank and feed the boilers while providing safety features such as overfill protection and low fuel cutoffs.

EnergyLogic technicians install the customized, 500-gallon waste oil storage tank inside the shipping container.

Solution No. 3: Install Six EL-500B Waste Oil Boilers

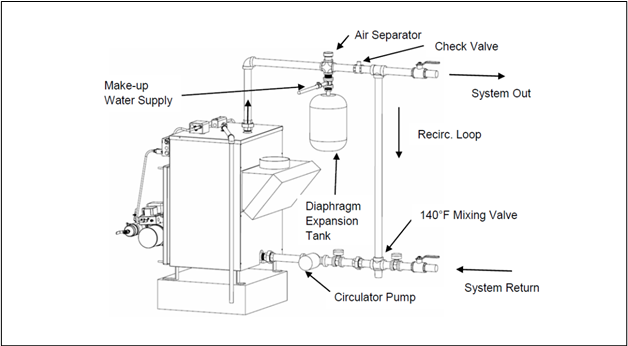

To generate enough hot water to wash the trucks and equipment, approximately 3,000,000 btu’s were required for this task. EnergyLogic designed a layout that would hole the 6 – 500,000btu boilers systems along with a fuel storage and reliable fuel delivery system. The layout also included all the plumbing, electrical and safety controls required for the producing of the hot water. The boilers inside the container also included the heat exchangers and expansion tanks for their closed loop systems. The boiler exhaust systems, service areas with parts storage and mounting racks were laid out and designed with accessibility in mind.

Six EnergyLogic 500B waste oil burners were installed inside the shipping container to heat a water tank and provide warm air in a new service area.

Each boiler has its own circulation pump and expansion tank to operate in a closed-loop system.

Solution No. 4: Fit Out with Electrical Power

The customer required a plug-in and go solution. To meet these demands, EnergyLogic also fit the shipping container with electrical power in addition to the boiler piping and controls. An actual 230v/50hz electric panel was installed to provide power to the boilers, internal lighting, ventilation fans and service plugs which all met the National Electric Code standards. The panel was strategically placed for easy access to match up for the customer’s incoming power as well.

Results

One of the most challenging aspects of this customized waste oil burner system was installing it into a shipping container that would be ocean worthy. The container was inspected and met all of the shipping criteria for the long journey.

Once the shipping container arrived, there was little additional work required to get the complete custom waste oil solution up and running.

As a result, the diamond mine no longer needs to dispose of waste oil off-site, reducing operational costs and helping to prevent environmental disasters such as accidental spillages. The customer now has an energy-efficient way to supply heat to their building and provide hot water to their water tanks.

Contact EnergyLogic Today for Your Custom Waste Oil Burner Solution

EnergyLogic has been at the forefront of innovation in the energy business since their heater development in the early 1980’s. Today, EnergyLogic prides itself on expanding on that early knowledge to meet our client’s biggest, most complex challenges. Together with our expertise and largest variety of accessories in the industry, we can design and implement a custom solution for any problem or space.

If you are interested in learning more about a custom waste oil heating solution, fill out our ‘Contact Us’ form at EnergyLogic.com or call us at 1-800-311-8828.